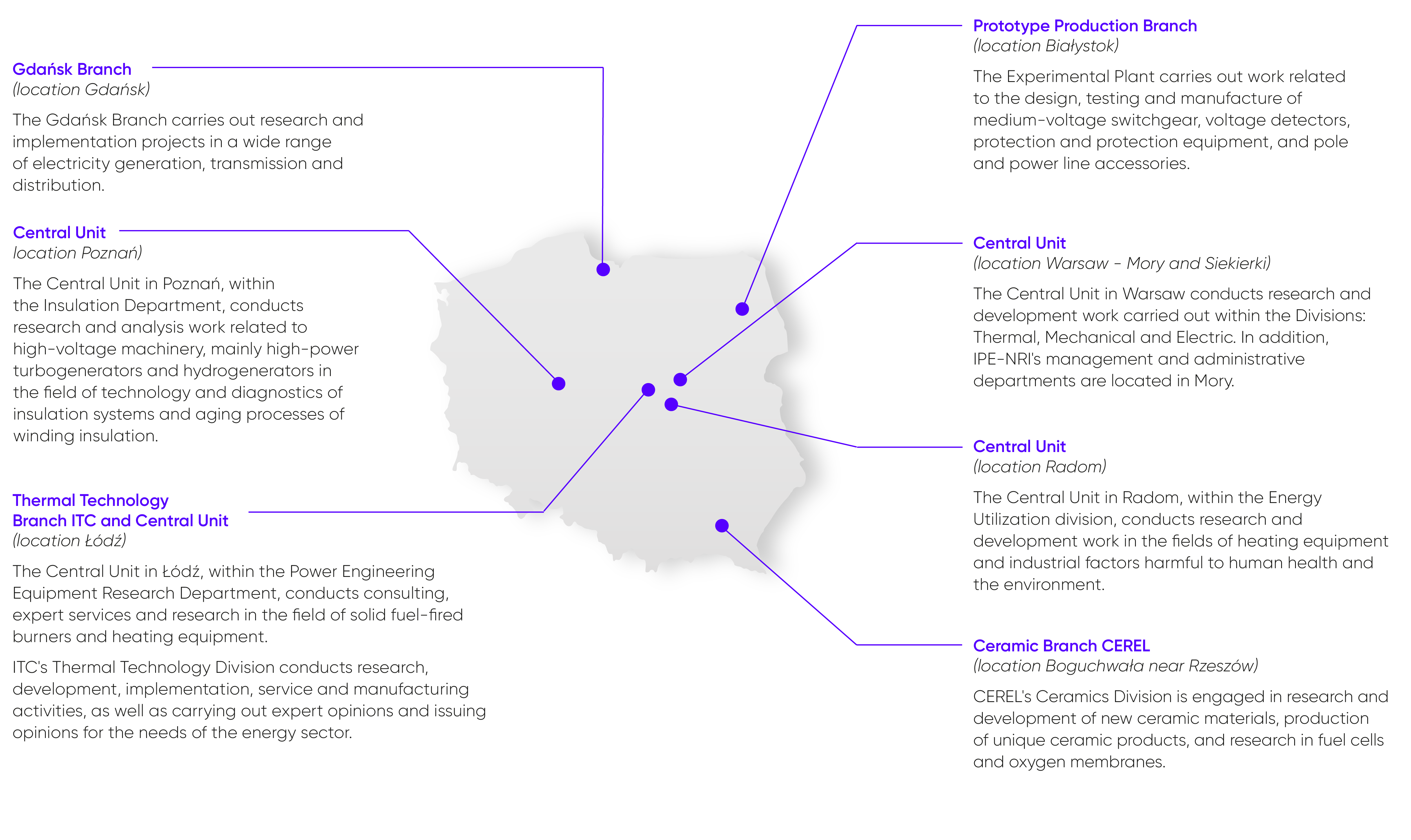

Instytut Energetyki

What is the Energy Utilisation Division?

The Energy Utilisation Division is one of the four divisions of the Central Unit of the Power Engineering Institute in Warsaw. The Division comprises the following units:

- UGA - Radiator and Fittings Testing Laboratory

- UOS - Environmental Protection Testing Laboratory

- USM - Management Systems Laboratory

- URP - Project Implementation Team

What does the Energy Utilisation Division do?

Among other things, research and development work is carried out in the units within the structure of the Energy Utilisation Division in the field of heating appliances and industrial factors harmful to human health and the environment. Within the framework of accreditation and notification No. 1452, assessment and verification of constancy of performance of central heating radiators according to the harmonised standard PN-EN 442-1:2015-02 (AVCP Assessment and Verification of Constancy of Performance, system 3) is performed, and testing of central heating fittings and thermostatic valves according to the harmonised standard PN-EN 215:2020-01 is carried out.

Contact us

|

Energy Utilisation Division 8 Wilcza St. 26-610 Radom |

Head of Energy Utilisation Division Marlena Małek, Eng. MSc. mobile.: +48 691 484 665 e-mail: |

What is the Center for Hydrogen Technologies (CTH2)?

The Centre for Hydrogen Technologies (CTH2), established in 2020 as part of the Institute of Power Engineering – National Research Institute, coordinates efforts related to the development and implementation of hydrogen technologies. The Center serves as a think tank that leverages its scientific and technical potential to conduct research, develop and deliver market products,  and provide comprehensive consulting services in the field. Additionally, it promotes knowledge of hydrogen technologies, with a special focus on the role of hydrogen in the ongoing energy transition.

and provide comprehensive consulting services in the field. Additionally, it promotes knowledge of hydrogen technologies, with a special focus on the role of hydrogen in the ongoing energy transition.

CTH2 brings together over 60 interdisciplinary researchers with expertise in such areas as process engineering, materials engineering, chemistry, physics, power engineering, automation and control engineering, and solid-state chemistry and physics. The Center for Hydrogen Technologies (CTH2) of the Institute of Power Engineering - National Research Institute was established in May 2020 as a response to new challenges in the development of hydrogen technologies in Poland.

CTH2 projects

In 2022, the Center coordinated the implementation of the task carried out under Priority Programme 5.1.1 ‘Support to the Climate Minister in the implementation of climate policy, financed by the National Fund for Environmental Protection and Water Management’:

Center for Hydrogen Technologies staff members participated in expert and consultative teams and public administration advisory bodies, including:

- Coordinating Council of the Sectoral Agreement for the Development of the Hydrogen Economy,

- Council of the Mazovian Hydrogen Valley,

- International Energy Agency, Annex 32: Advanced Fuel Cells,

- European research initiative on Green Hydrogen,

- Hydrogen Europe Research,

- European Energy Research Alliance, Fuel Cells and Hydrogen,

- National Environmental Council,

- Hydrogen Expert Panel of the Chamber of Commerce of Natural Gas,

- Board of the Podkarpackie Hydrogen Valley.

Representatives of the Center were leaders of task forces implementing the indicator goals of the Polish Hydrogen Strategy within Group 1 of the Hydrogen Alliance: Hydrogen Production, coordinated by Prof. Jakub Kupecki, D.Sc:

- Team G1.1: Launch of national production of new components, hydrogen technologies based on national scientific and research potential,

- Team G1.2: Realisation of R&D and basic research in the field of electrolysers (including definition of an optimal power range of electrolysers to be installed in Poland),

- Team G1.8: Decarbonisation of the steel and cement industries.

The Center has represented the Institute of Power Engineering in Hydrogen Valleys at industry events, trade fairs, popular science events and media debates, including: 7th Scientific Conference ‘Energy Security - Pillars and Development Perspective’, Hydrogen in the Economy, New Energy Model, International Conference and Expo on Advanced Ceramics and Composites (ICACC2022), World Fuel Cell Conference, 8th Energy Congress Security of Energy Supply in Times of Transition, International Conference on Electrolysis, 5th International Workshop on Degradation Issues of Fuel Cells and Electrolysers, Ceramics in Europe, 7th International Conference on Contemporary Problems of Thermal Engineering (CPOTE 2022), 17th Conference on Sustainable Development of Energy, Water and Environment Systems (SDEWES), 241st Meeting of the Electrochemical Society (ECS) and others.

The Center has represented the Institute of Power Engineering in Hydrogen Valleys at industry events, trade fairs, popular science events and media debates, including: 7th Scientific Conference ‘Energy Security - Pillars and Development Perspective’, Hydrogen in the Economy, New Energy Model, International Conference and Expo on Advanced Ceramics and Composites (ICACC2022), World Fuel Cell Conference, 8th Energy Congress Security of Energy Supply in Times of Transition, International Conference on Electrolysis, 5th International Workshop on Degradation Issues of Fuel Cells and Electrolysers, Ceramics in Europe, 7th International Conference on Contemporary Problems of Thermal Engineering (CPOTE 2022), 17th Conference on Sustainable Development of Energy, Water and Environment Systems (SDEWES), 241st Meeting of the Electrochemical Society (ECS) and others.

In 2022, the CTH2 staff made study visits to the University of Aveiro, Portugal, DTU, Denmark, Colorado Fuel Cell Center, Colorado School of Mines, Golden, CO, and the National Fuel Cell Research Center, University of California, Irvine, CA, USA, as part of the ongoing Polish-American SUPER-SOE project: Investigation of high temperature co-electrolysis of carbon dioxide and steam in solid oxide electrochemical cells operated at elevated pressure, which is carried out under the SONATA BIS programme of the National Science Centre (SONATA-BIS 2021/42/E/ST8/00401).

Contact us

What is the Power Engineering Equipment Research Department?

The Department has more than 40 years of experience in testing boilers, burners and heating equipment fired by solid fuels. The Department also provides consulting and expert services in the above-mentioned field. The Department's clients are domestic and foreign (Germany, Latvia) principals. The Department cooperates with manufacturers affiliated with the Chamber of Commerce of Renewable Energy Equipment.

What does the Power Engineering Equipment Research Department do?

The Power Engineering Equipment Research Department's more than 40 years of experience in the design and testing of heating equipment enables us to:

- design and modernization of low-power heating equipment (up to 1 MW),

- rental of a measuring station (with or without an operator),

- testing of pellet burners,

- testing of capacity water heaters according to PN-EN 12897+A1:2020-03,

- testing of hot water storage tanks,

- testing of other low-power heating devices (e.g. air heaters).

- residential solid fuel burning appliances according to PN-EN 16510 series of standards

- thermo-emission tests in the combustion of alternative fuels,

- conducting research and development in the power industry of low-power heating devices (up to 1 MW).

As part of the Department of Power Equipment Testing, there is an Accredited Laboratory (No. AB 087), which performs testing of boilers and equipment for solid fuels. It is the only laboratory in Poland accredited to test heating boilers with thermal power up to 1 MW. Obtaining a positive result of thermal-emission tests for compliance with PN-EN 303-5:2021-09 and/or PN-EN 303-5+A1:2023-05 fulfills the requirements of the European Commission Regulation (EU) 2015/1189 of April 28, 2015 on the implementation of Directive 2009/125/EC of the European Parliament and of the Council with regard to ecodesign requirements for solid fuel boilers allows boilers to be marketed in the territory of the European Union.

Within the framework of accreditation and notification No. 1452, the assessment and verification of constancy of performance of products (AVCP Assessment and Verification of Constancy of Performance, system3) is carried out according to the Regulation of the European Parliament and of the Council (EU) No. 305/2011 of March 9, 2011. (CPR) establishing harmonized conditions for the marketing of construction products and repealing Council Directive 89/106/EEC according to harmonized standards:

- solid fuel space heaters according to PN-EN 13240:2008,

- fireplace inserts for solid fuels PN-EN 13229:2002,

- cookers for solid fuels PN-EN 12815:2004,

- accumulation space heaters according to PN-EN 15250:2009,

- pellet-fired space heaters according to PN-EN 14785:2009.

Meeting the requirements of the above standards during the assessment of the notified body, together with documented factory production control, allows the equipment to be placed on the market in the territory of the European Union.

Boiler and Heating Equipment Testing Laboratory offers accredited testing:

- room heaters according to PN-EN 16510-2-1:2023-06,

- built-in appliances, including those with open fires (fireplace inserts) according to PN-EN 16510-2-2:2023-06,

- room heaters, built-in appliances and stoves with mechanical feeding of wood pellets according to PN-EN 16510-2-6:2023-06,

- solid fuel boilers according to PN-EN 303-5:

- space heaters according to PN-EN 13240:2008,

- fireplace inserts according to PN-EN 13229:2002,

- solid fuel cookers according to PN-EN 12815:2004,

- storage space heaters according to PN-EN 15250:2009,

- pellet-fired space heaters according to PN-EN 14785:2009.

If you are interested in our offer, please fill out the inquiry form and send a scan of it to the following email address:

Why should you choose our services?

The Power Engineering Equipment Research Department has an experienced team of experts that offers comprehensive services in the field of testing boilers, burners and heating equipment fired by solid fuels.The Department has a Laboratory that has an accreditation certificate from the Polish Accreditation Center No. AB 087 - registration card. The Department has references from companies such as:

- Defro

- Hamech

- Lazar

- Moderator

|

Power Engineering Equipment Research Department LG ul. Dostawcza 1 93-231 Łódź mobile: +48 42 64 00 821 |

Head of the Department Karolina Tomczyk - Karasek, Eng, MSc mobile: +48 609 799 455 |

What is the Department of High Temperature Electrochemical Processes?

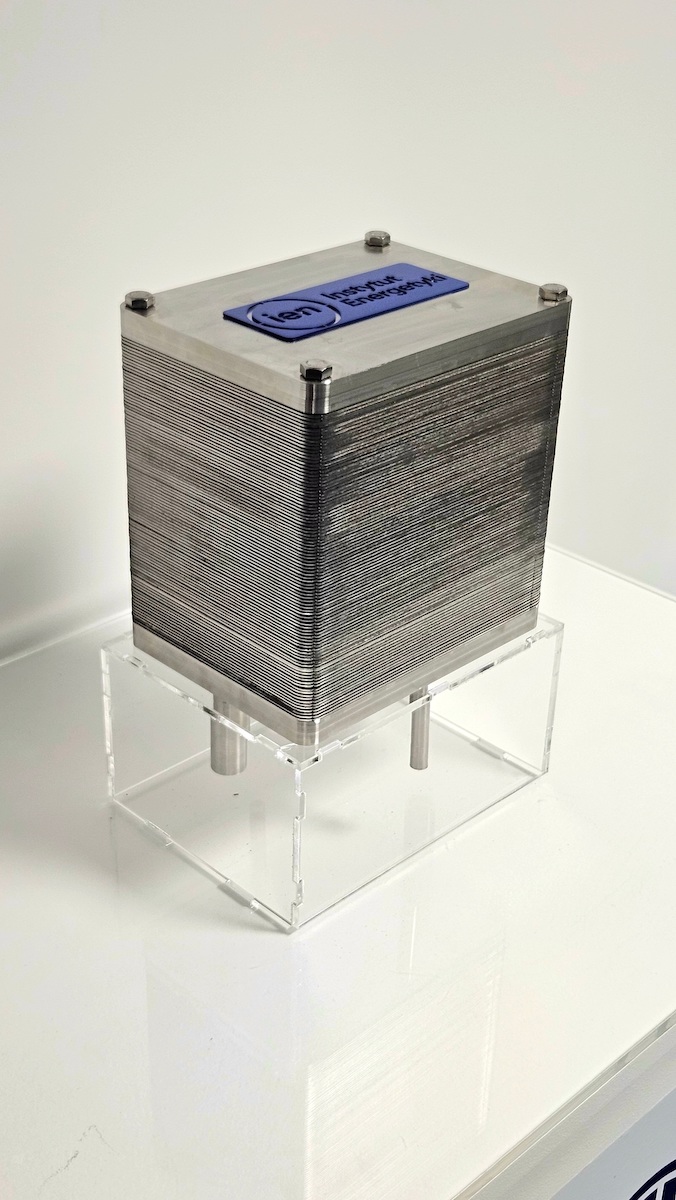

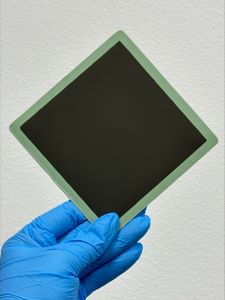

The Department of High Temperature Electrochemical Processes (CPE) is an interdisciplinary team consisting of specialists and experts from the fields of energy, chemical engineering, materials engineering, process engineering and related areas. The unit's activities focus on the development of hydrogen technologies, with particular emphasis on the topic of solid oxide electrochemical cells (SOC, or Solid Oxide Cell), which represent a promising solution in the context of decarbonization of hard-to-electrify areas of the economy.

What does the Department of High Temperature Electrochemical Processes do?

We carry out numerous projects involving work in the nature of research, development and implementation, as well as commercial contracts for the supply of fixed-oxide cell installations. We are also open to cooperation in which our team of specialists will advise and prepare solutions tailored to individual customers including: business entities, central administration, international and foreign institutions in the field of:

- highly efficient generation of electricity and heat by electrochemical processes - fuel cell mode (SOFC mode),

- production of zero-emission hydrogen and derivatives (including CO2 utilization) by high-temperature electrolysis and co-electrolysis (SOE and co-SOE modes, respectively), also taking into account ammonia (NH3), as a pure hydrogen carrier,

- Power-to-X and X-to-Power solutions,

- storage of electricity, heat and in other forms, among others, using reversible rSOCs (SOE-SOFC switching mode),

- numerical calculations and computer simulation of electrochemical and chemical processes and power plants,

- design and construction of power systems,

- technical consulting in the field of new hydrogen technologies and the broader power industry.

Download FAQ

Why should you choose our services?

We have a unique laboratory infrastructure for studying electrochemical processes from the level of individual cells and components to complete energy systems based on SOC cells of different functionality and dedicated size. CPE team members also apply proprietary and unique solutions used in numerical studies and modeling of complex hydrogen-based processes and systems.

We apply global standards for characterization of solid oxide cells. We cooperate with leading European and global institutions, including universities, research institutions and directly with industry. The team bases its experience on numerous projects funded by the European Commission, the U.S. Department of State (DoS), the U.S. Department of Energy (DoE), the National Center for Research and Development (NCBR), the National Science Center (NCN), the Ministry of Science and Higher Education (MNiSW) and directly by industry.

We apply global standards for characterization of solid oxide cells. We cooperate with leading European and global institutions, including universities, research institutions and directly with industry. The team bases its experience on numerous projects funded by the European Commission, the U.S. Department of State (DoS), the U.S. Department of Energy (DoE), the National Center for Research and Development (NCBR), the National Science Center (NCN), the Ministry of Science and Higher Education (MNiSW) and directly by industry.

The SOC/SOE/SOFC technology being developed at the High-Temperature Electrochemical Processes Plant addresses the global challenges of the hydrogen economy and minimizing the effects of climate change, particularly focusing on the production of hydrogen and synthetic fuels using renewable energy. In addition to the aforementioned activities, the plant is also focusing on the development of new materials for SOC cells to reduce the consumption of critical raw materials, as well as solutions to enable their reuse in line with recycling and closed-loop economy technologies.

The plant has a unique laboratory infrastructure for studying electrochemical processes from the microstructure level of materials to complete energy systems based on fuel cells and electrolyzers for hydrogen generation. CPE team members use commercial and proprietary codes for numerical studies of complex processes and systems. The most advanced calculations use a multi-process high-power computing cluster.

CPE uses global standards for the characterization of solid oxide fuel cells (SOFCs), and collaborates with leading European and global institutions, including universities, research institutions and directly with industry. The team has experience gained from numerous projects funded by the European Commission, the U.S. Department of State (DoS), the U.S. Department of Energy (DoE), the National Center for Research and Development (NCBR), the National Center for Science (NCN), the Ministry of Science and Higher Education (MNiSW) and directly by industry. The technology being developed at the Department of High-Temperature Electrochemical Processes is a response to global challenges in the hydrogen economy, particularly the production of hydrogen and synthetic fuels using renewable energy.

Contact us

|

Department of High Temperature 36 Augustówka Street 02-981 Warsaw |

Head of the Department prof. Jakub Kupecki +48 797 205 147 |