Instytut Energetyki

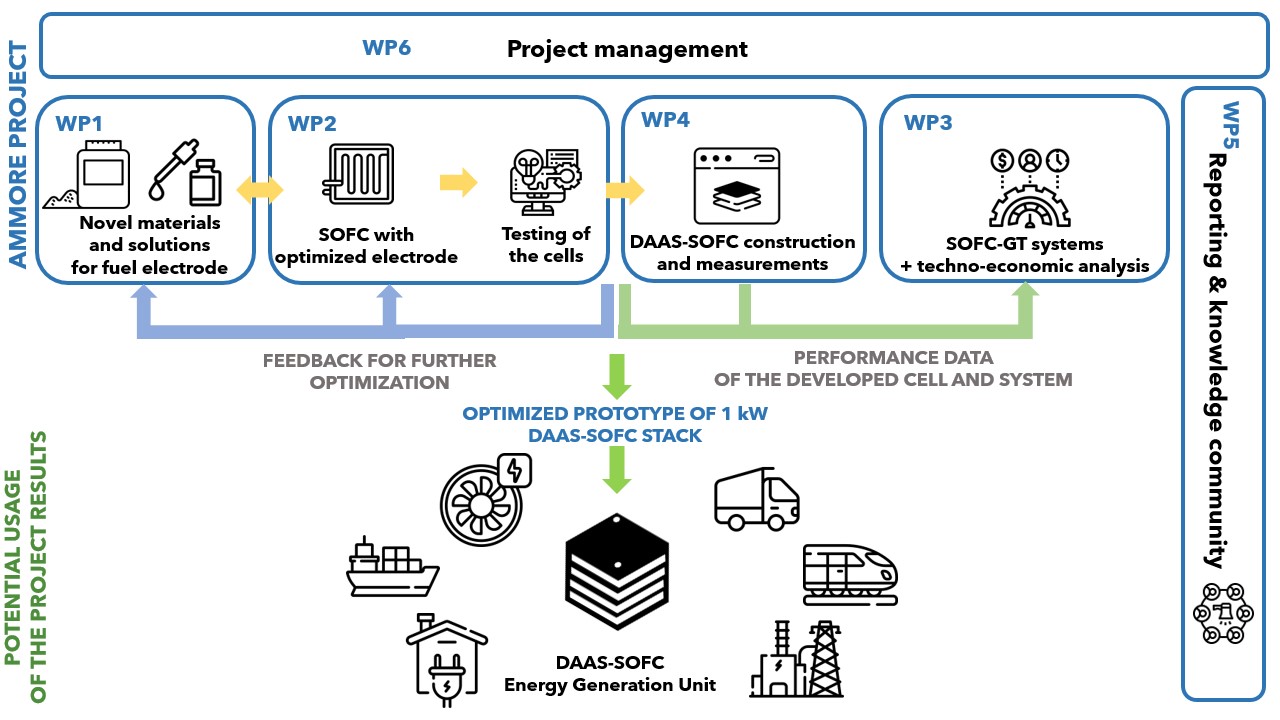

The overall objective of AMMORE project is to develop a standardized modular and multipurpose kW-class energy generation unit (EGU) based on an intermediate temperature solid oxide fuel cell (SOFC) stack powered by ammonia. A key goal is to position ammonia as a sustainable, efficient, and economically viable fuel for SOFC-based systems. The project will accomplish this by developing advanced materials, adapting cell fabrication techniques, optimizing stack conditions for ammonia compatibility, and designing durable systems for a variety of applications, including long-distance transportation, hybrid SOFC-gas turbine solutions, and distributed energy production. Through extensive testing, safety protocol development, and techno-economic analysis, AMMORE aims to demonstrate the feasibility and scalability of ammonia-powered SOFCs as low-emission alternatives to traditional carbon fuels. The primary aim of the project will be achieved through a step-by-step approach, targeting the following objectives:

- Tailoring the design of the state-of-the-art (SoA) anode-supported SOFC to use ammonia as sustainable fuel (DAAS-SOFC, which stands for Direct Ammonia Anode Supported SOFC).

- Designing and developing a customized fuel electrode with superior catalytic activity and enhanced durability for facilitating direct electrochemical NH3 oxidation, thereby enabling the removal of an external ammonia cracking reactor from the system.

- Investigating the durability of single cells fed by NH3 and defining the stable modus operandi for DAAS-SOFC to minimize degradation rates.

- Enhancing the existing IEN-PIB SOFC stack design for the usage of ammonia and demonstrating operability on short stacks (5-10 cells).

- Developing a modular and multipurpose EGU to convert ammonia to electricity and heat with outstanding high-efficiency. EGU will be based on a 1 kW class DAAS-SOFC stack.

- Studying the operability of the EGU, including long-duration tests (1,000+ hours) with NH3 and examining fuel flexibility (performance on H2 and H2-N2/NH3 mixtures) for alternative applications.

- Adjusting the design to safety protocols and fuel delivery solutions for ammonia in SOFC systems.

- Completing modeling and techno-economic variant studies on the EGU's applicability across various sectors, e.g. transportation and energy sectors, including analysis of the hybrid DAAS-SOFC-gas turbine systems as one of the options for industrial deployment.

The AMMORE project objectives are tailored to cover technical, environmental, and economic aspects of using ammonia as a clean fuel source. The project aligns closely with the CETPartnership Joint Call 2024 Call Module CM2024-05 Hydrogen & renewable fuels, focused on advancing hydrogen and renewable fuels, by developing a scalable, ammonia-fueled multipurpose EGU. The intended, measurable outcomes – a prototype EGU system with new materials solutions for SOFC stack, together with techno-economic analysis, will contribute to the development of efficient and environmentally friendly technical solutions, which are essential for achieving a climate-neutral economy. The Technology Readiness Level (TRL) is expected to rise from TRL4 at the start of the project to TRL6 by its completion. The project's objectives are ambitious yet achievable, thanks to a well-structured work plan, precise task division, and the cumulative expertise of the project consortium’s members, complemented by diverse skills and knowledge.

Ammonia-fueled solid oxide fuel cells (SOFCs) are a promising technology for efficient, low-emission power generation. Ammonia offers a carbon-free, easily transportable fuel, making it attractive for integration with hybrid systems, including gas turbines.

This research focuses on developing Direct Ammonia Anode-Supported SOFCs (DAAS-SOFCs), addressing multiply challenges such as controlled ammonia cracking, nitridation of steel components or the anode degradation, as well as thermal management. By combining materials engineering, electrochemical testing, system modeling, and techno-economic analysis, the study aims to advance the DAAS-SOFC technology toward commercialization and support the transition to renewable e-fuels.

Research Methodology

The methodology integrates a comprehensive, industrialization-oriented approach, encompassing:

-

Materials Research – development and evaluation of new materials for cells and stacks.

-

Solid-State Electrochemistry – assessment of cell and stack performance, durability and degradation.

-

Modeling and Construction Activities – design, testing and optimization of components and systems.

-

Techno-Economic Analysis – evaluation of market introduction feasibility.

By combining these interdisciplinary but complementary approaches, the research aims to develop innovative solutions while systematically achieving all declared objectives.

Enhancement of Electrochemical Performance in DAAS-SOFC

To improve electrochemical performance and suppress degradation of DAAS-SOFC, the methodology includes:

- Partial substitution of YSZ in Ni-YSZ cermet with mixed ionic-electronic conductors (MIEC) based on:

- Perovskite structure titanates: donor-doped Sr(Ln)TiO₃

- Pyrochlore structure titanates: Ln₂Ti₂O₇

- These components will be modified with appropriate substitutes to enhance electrical conductivity and electrocatalytic activity.

Advantages of titanate ceramics over ceria-based solid solutions:

- Higher electronic conductivity

- Enhanced dimensional stability (low chemical expansion) under operational conditions

NH₃-Resistant Materials and Surface Treatments

To prevent nitriding and cracking of the cell:

- Copper or copper alloys will be applied on surfaces exposed to ammonia, including the anode compartment, interconnects, and cell support surfaces.

- Deposition methods:

- Spray-coating or electrophoretic deposition for interconnects

- Screen-printing (with pore-forming agents) for support surfaces

- Anode support impregnation: Solutions or suspensions promoting NH₃ cracking in support pores without affecting electrochemical performance

- Tentative electrocatalysts: Ni modified with basic oxides (SrO, BaO) supported on Ln oxides or titanates

Cell Preparation Methods:

- High-pressure injection molding for support

- Screen printing for functional layers

- High-temperature sintering with optimized paste composition and sintering temperatures

Characterization of Cells and Stacks

The following techniques will be used:

- Electrochemical measurements: Current-voltage characteristics (CVC), electrochemical impedance spectroscopy (EIS), short-term galvanostatic monitoring

- Data analysis: Distribution of relaxation times (DRT)

- Fueling: Ammonia (99.98%) under strict safety protocols; green ammonia will be considered in techno-economic scenarios

- Gas analysis: Fourier transform infrared spectroscopy (FTIR) or other precise techniques

Temperature measurement challenges:

- Tight, compact, layered stack structures make internal thermocouple placement difficult due to short-circuit risk

- Solution: thermocouples placed in the fuel channel at the inlet of individual SRUs and between elements of the same potential to monitor areas prone to cracking safely

1 kW DAAS-SOFC Test Rig

A specially designed test rig will allow:

- Finite element analysis (FEA) and computational fluid dynamics (CFD) to optimize structural and process solutions

- Universal testing platform to study DAAS-SOFC under various operating conditions

- Ammonia-resistant components and compatible seals

- Automated PLC-based control system with HMI for monitoring startup, cooldown, long-term operation

- Safety systems: overpressure, overheating, gas leakage detection, emergency shutdown, and purge procedures

Measurements during experiments:

- Electrochemical (EIS with DRT, CVC)

- Temperature, pressure, gas composition (FTIR, GC, or equivalent)

- Exhaust gas analysis for ammonia decomposition monitoring and gas turbine operation

Post-mortem analysis:

- SEM, SEM-EDS, XRD, TGA, profilometry, GDEOS

- Focus on nitriding, coarsening, functional layer deterioration, dimensional changes, and layer detachments

Gas Turbine (GT) Test Stand

- Designed to measure thrust, thermal efficiency, isentropic efficiency, and turbine power

- Equipped with thermocouples and pitot tubes for precise pressure measurements

System Modeling and Techno-Economic Analysis

- 1D DAAS-SOFC and NH₃ combustion GT models for EBSILON Professional®

- Models validated with test rig data

- Used to design and optimize:

- Standalone SOFCs

- SOFCs with NH₃ crackers

- Integrated SOFC-GT systems

- Performance analysis: efficiency, emissions, and balance of plant (BoP) optimization

- Techno-economic evaluation: production costs, operational feasibility, environmental impact, life-cycle assessment (LCA), and market factors

Expected Outcomes

- Creation of an operable NH₃-fueled SOFC EGU reaching TRL 6

- Comprehensive data and insights to guide further development and market introduction

- Support for the transition toward renewable e-fuels and low-emission technologies